RO Model: LG SW 440 R

Active area: 440 ft2 (41 m2), 37.5 m3/d (9,900 GPD), Stabilized salt rejection: 99.85%

Background

Algeria’s growing urban population, environmental changes, and limited water resources continue to pose significant challenges. More than half of the country’s urban residents face intermittent water supply shortages. To combat this, the Algerian government has implemented a large-scale desalination program, including the Mostaganem SWRO Desalination Plant. This plant produces 200,000 m³ of drinking water daily, supplying over one million people. Since 2016, the plant has replaced with LG SW 440 R membranes helping deliver high-quality drinking water to the region.

| Project Introduction | |

| Capacity | 200,000 m3/day |

| Configuration | 8 double-rack trains with 304 pressure vessels each; 7 elements per vessel |

| Recovery | ERI PX-220 |

Outstanding Performance in On-site Pilot Testing

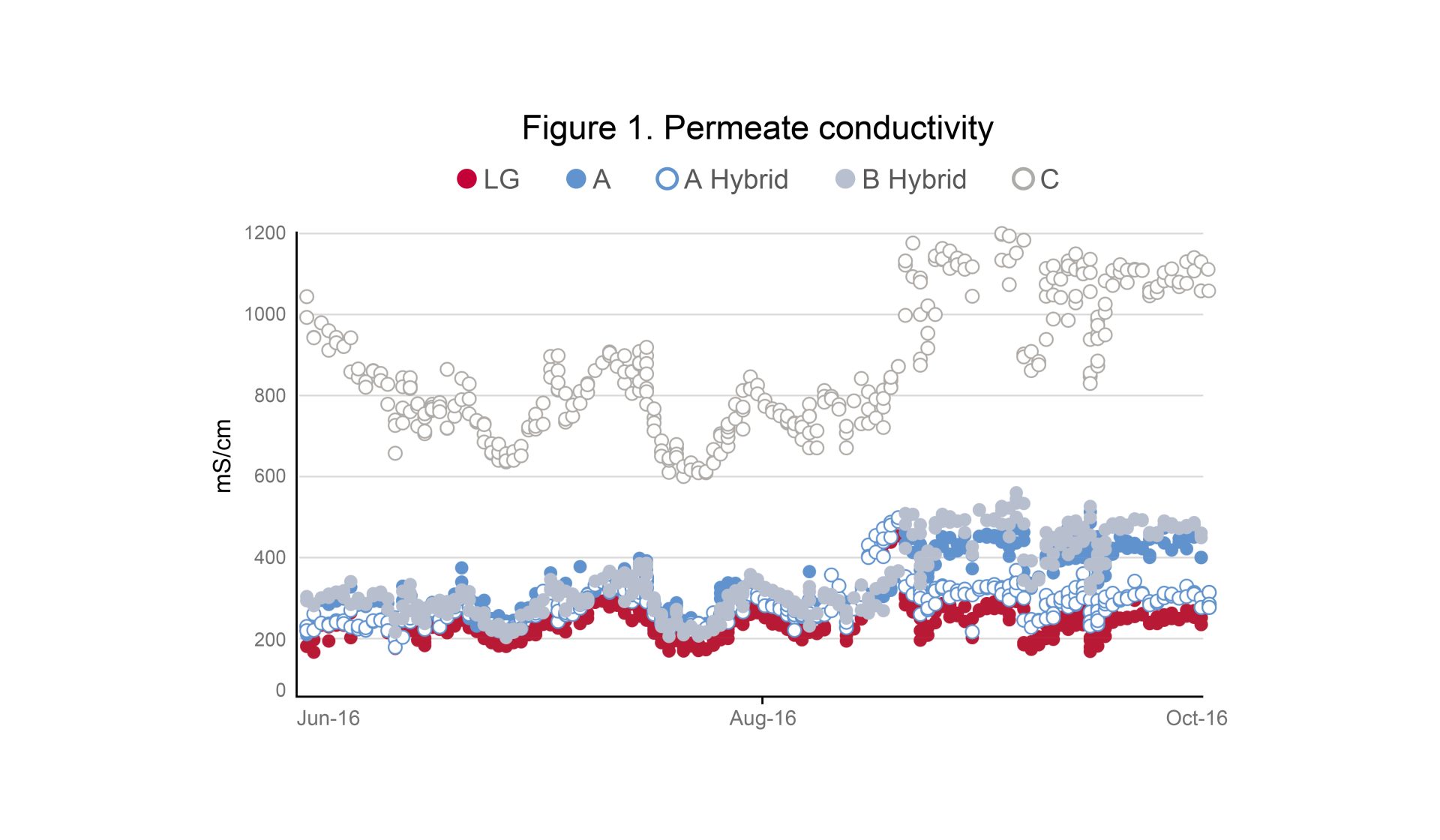

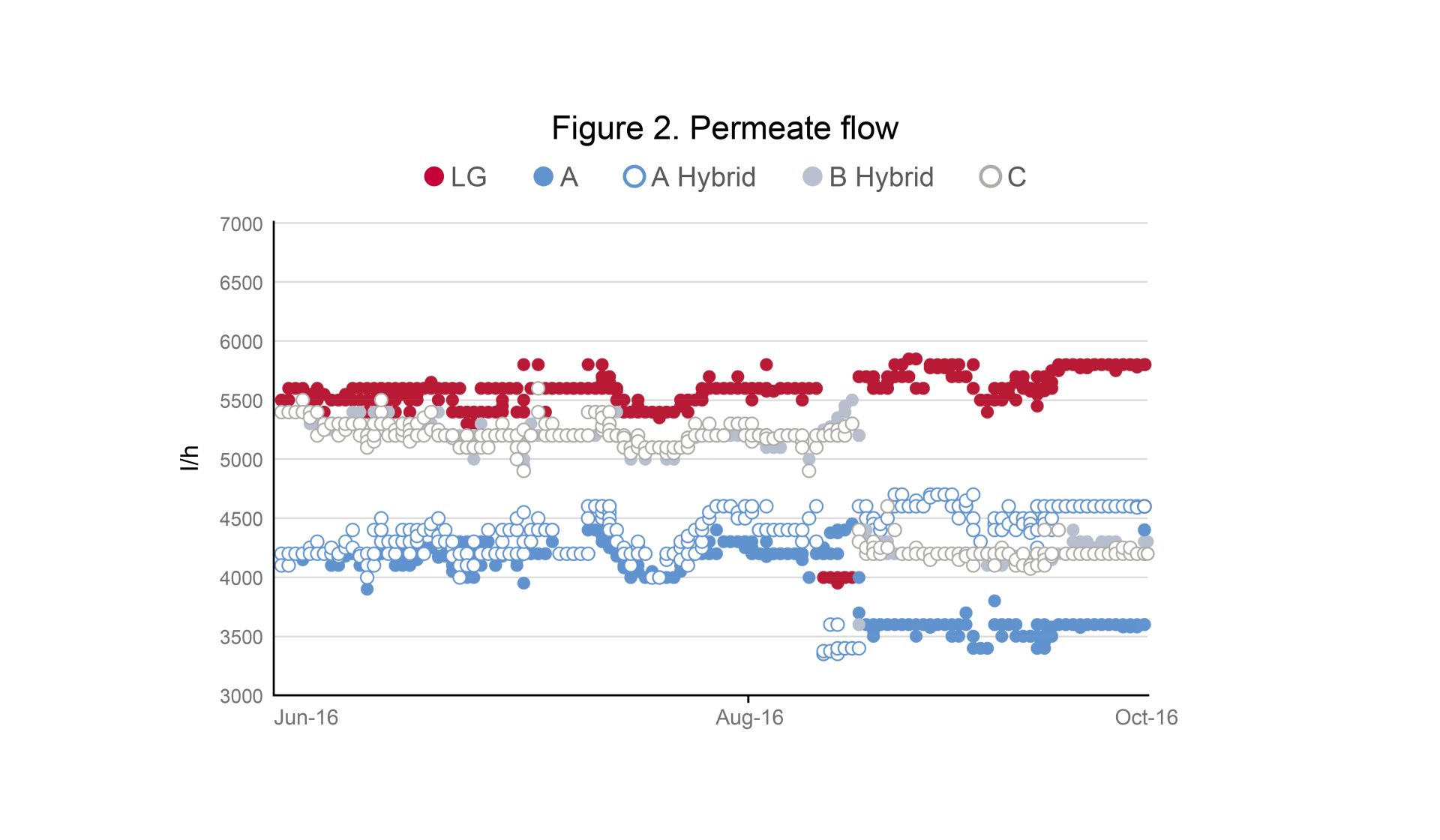

By 2016, the Mostaganem plant had been in operation for five years, and had begun to show signs of membrane aging, including increased energy consumption and decreased permeate quality. To address these issues, a pilot test was conducted to find the optimal solution. LG Water Solutions participated in this test with its LG SW 440 R product, equipped with innovative *TFN technology. The pilot test included membranes from four different manufacturers, allowing a direct performance comparison. LG SW 440 R membranes outperformed the others by achieving the highest permeate flow, lowest permeate conductivity, and highest boron rejection (see Figure 1). As a result, LG SW 440 R membrane was selected to replace the membranes in Trains 1 and 2.

*TFN: Thin Film Nanocomposite

Excellent Performance Leads to Strategic Replacements’

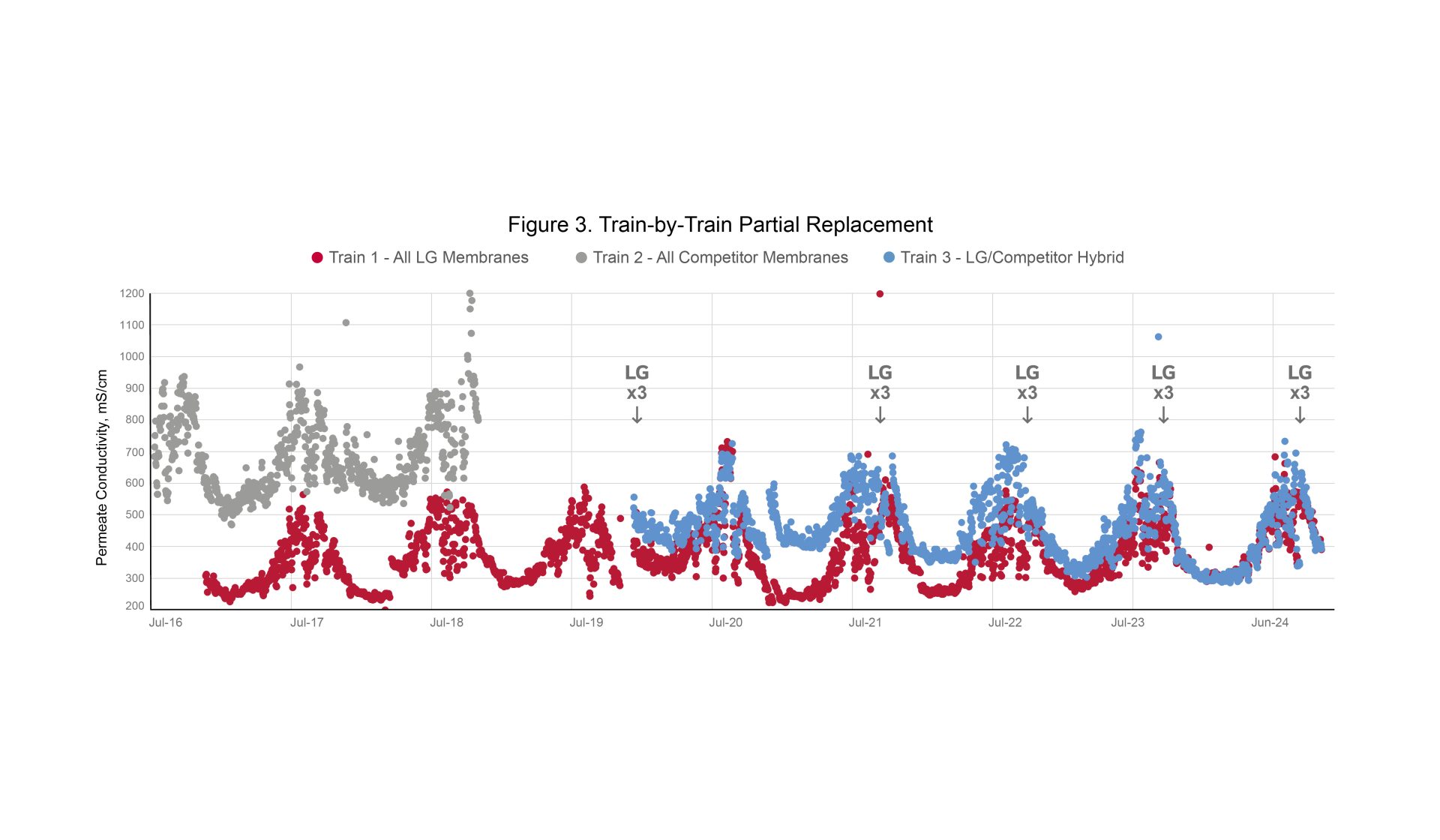

Since 2016, Trains 1 and 2 have demonstrated stable performance in both permeate flow and salt passage. Over the past eight years, the system required only six chemical cleaning ensuring consistent performance throughout. Membrane replacements have also been strategically managed, with timely replacements maintaining optimal performance and extending system lifespan. This proactive approach has ensured that the SWRO operation remains stable and efficient.

Impressed by the operational results demonstrated by LG SW 440 R membranes in Trains 1 and 2, the Mostaganem plant decided to expand the use of LG Water Solutions’ membranes across all 14 remaining trains. The consistent delivery of water with lower conductivity and reduced boron levels demonstrated LG SW 440 R membranes’ superior performance and outstanding reliability, ensuring compliance with stringent water quality standards (see Figure 2).

By 2024, the plant had replaced 98% of its membranes with LG Water Solutions’ TFN membranes. This strategic replacement improved water quality and enhanced the overall efficiency of the plant. The transformation also significantly increased production capabilities, leading to high levels of customer satisfaction and reinforcing LG Water Solutions’ reputation for excellence.

Outcome

Today, the success of the Mostaganem plant stands as a powerful testament to the proven performance of LG Water Solutions’ TFN membranes. What began as a single-train replacement evolved into a full-plant transformation, driven by our membrane technology and our ongoing commitment to meeting the evolving needs of our customers. By consistently delivering exceptional water quality and innovative solutions, LG Water Solutions has set a new standard in the desalination industry. This study highlights both leadership in advancing SWRO technology and our commitment to ensuring sustainable, high-quality water supply for communities worldwide.