Product Type: High Rejection SWRO

RO Models: LG SW 440 SR, LG SW 440 R

Background

NanoH₂O™ seawater reverse osmosis (SWRO) membranes incorporated with Thin-Film Nanocomposite (TFN) technology, provide the highest salt rejection in the industry, up to 99.89%. NanoH₂O™ SWRO membranes have also demonstrated outstanding boron removal performance, addressing a critical water quality concern for both drinking and irrigation water across the Mediterranean region.

Malta is an archipelago of three islands in the Mediterranean Sea with no major rivers and the sparse annual rainfall of only about 500 mm. Due to its limited freshwater sources, Malta relies heavily on desalination. The Pembroke desalination plant, located on the main island, is the country’s largest installation with a total production capacity of 54,000 m³/day. The plant consists of 12 single-pass trains operating at 42% recovery. The feed water comes from beach wells with low Silt Density Index (SDI), typically below 1, low annual temperature variation of 19 to 22°C, and pH adjusted to 6.7 using sulfuric acid. Despite low SDI, the plant experiences severe fouling and requires frequent cleaning. (see Table 1)

| Table 1. Pembroke Desalination plant specifications | |

| Client | Water services corporation |

| Start-up Date | 2016 |

| Feed Water Intake | Sea water |

| Application | Portable water |

| Plant Configuration | 8 trains (Currently 6 in operation) – 45 pressure vessels each – 7 elements per pressure vessel |

| Recovery | 42% |

| Project Capacity | 54,000 m3/day |

| Total Number of LG Chem Elements | 2,520 (1,890 istalled) |

Long-Term Boron Rejection

When NanoH₂O™ SWRO membranes were first installed at the Pembroke desalination plant, the maximum levels of boron and conductivity of the product water were very restrictive, 0.9 mg/l and 400 µS/cm respectively. Boron removal was particularly challenging due to the relatively low pH of the feed water, which significantly reduces boron rejection efficiency by RO membranes. NanoH₂O™ SWRO membranes, which have demonstrated exceptional boron removal across numerous locations in the Mediterranean region and beyond, have achieved individual membrane boron rejection rates above 95%. As a result, the permeate quality consistently met the stringent boron limits of 0.9 mg/L. In 2023, local drinking water regulations were updated to increase the permissible boron concentration to 1.5 mg/L, further affirming the suitability of NanoH₂O™ SWRO membranes for long-term compliance.

Proactive Technical Supports for Fouling Mitigation

Despite the low SDI levels of the feedwater, RO membranes in the Pembroke desalination plant experiences severe membrane fouling, an issue that compromises membrane performance and increases maintenance cost. In response, NanoH₂O’s technical support team evaluated the membrane performance using our state-of-the-art cloud-based normalization and monitoring software QSee. Based on the observed trends, an alternative membrane configuration was proposed to reduce the maximum flux of the lead elements and achieve a more uniform flux distribution across the pressure vessels. This modification successfully mitigated fouling, stabilized system performance, and stopped the increasing frequency of Clean-In-Place (CIP), all while maintaining stringent product water quality standards.

Performance after Multiple CIP : High Rejection and Stability

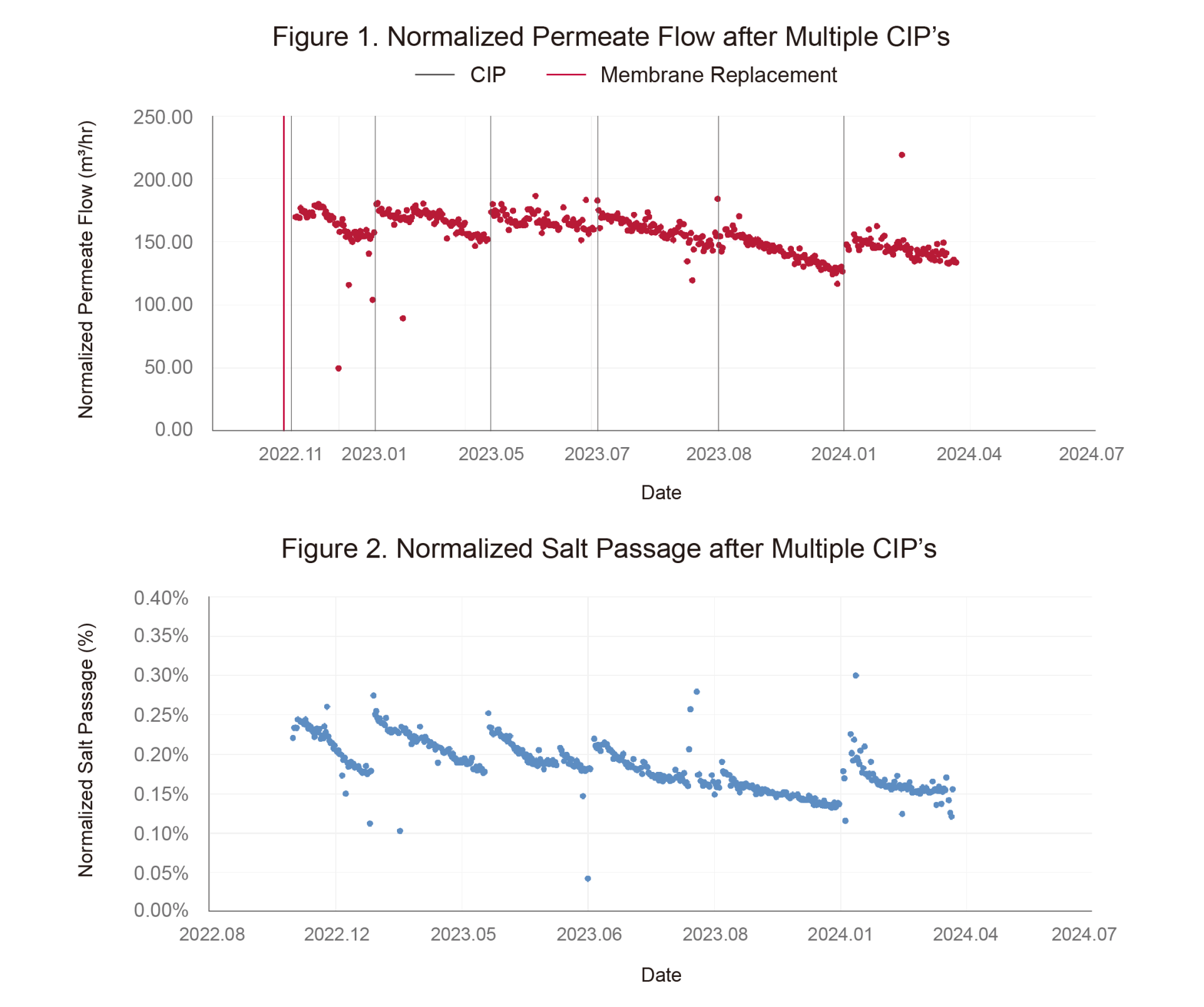

Regular CIP procedures are essential for maintaining the efficiency and lifespan of RO membranes. At Pembroke, NanoH₂O™ SWRO membranes have undergone multiple CIP cycles at intervals varying from 4 to 10 months, depending on operation conditions. The membranes exhibited a gradual decline in normalized permeate flow, which is a typical phenomenon from membrane fouling, but the performance was recovered well after each CIP showing no significant deterioration of membrane performance after multiple CIP’s. This durability, combined with their industry-leading salt rejection, highlights the membranes’ long-term stability and reliability, consistently meeting the product water quality over extended operation time.

Conclusion

Over more than ten years of continuous operation at the Pembroke desalination plant, NanoH₂O™ SWRO membranes have demonstrated exceptional performance in key areas: boron rejection, fouling resistance, salt rejection, and post-CIP recovery. These results highlight the NanoH₂O™ SWRO membranes’ value and resilience in high-demand applications. As global challenges on seawater desalination grow, NanoH₂O™ SWRO membranes continue to set the benchmark for innovation, reliability, and efficiency in seawater desalination.